Technology

In these decades of low-growth economy under stagnating situation,

1

2

3

-

1Main Choice of Substrate Films

Polyester film, vinyl chloride film, polypropylene film, synthetic paper film, polystyrene film, polyimide film, polyolefin film, aluminum evaporated film, etc.

-

2Main Choice of PSAs

Strong, Removable, Fine, UV cutting, Colored, Flame Retardant and Laminating PSA, etc.

-

3Main Choice of Release Paper & Films

Glassine Paper, High Quality Paper, Polyester Film, Polypropylene Film, etc.

* In addition to the above, there are various types of base films, adhesives and release materials.

Coloring / Function Added Technology

Main functions of PSA-film Product

Coating Technology

- Matte coating

- IJ coating

- Specific Coating

- Embossing etc.

Function Imparting Technology

- Heat Shielding Function

- Improved Coloring / Concealment

- Improved Flame Retardant

- Conductivity etc.

Process Technology

- Flat PSA

- MATRIX PSA

- Tack-Emboss etc.

Support for both "Evaluation Sample of Small-scale Trial" & "Measured Properties, Estimated Effects based on your Conditions"

Coloring /Function Added Technology

| Heat Shielding Function |

|

|---|---|

| Coloring / Concealment |

|

| UV Cutting |

|

| Flame Retardant Function |

|

| Electric Conductive Function |

|

| Alkaline Soluble |

|

Coloring

To make an original transparent PSA got coloring is intended that it becomes easier identified in visual.

The finish with the colored PSA application can make a difference depending on the compatibility of the PSA with the dye / pigment with our coating technique.NEION makes use of the technology that has been cultivated for many years, and is also capable of adjusting color shade.

Overcoating

For example, to achieve beautiful printing with an ink-jet printer, the film surface should be coated with an ink-accepting layer on our own technology.

NEION can give various functions on the surface of the main PSA-film, in addition to the PSA as well.

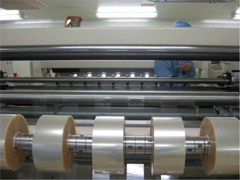

Advanced Equipment to Meet Customer Needs

We respond to customers' various needs with advanced functional & productive equipment. Based on NEION's unique development system, we continue to focus on the customer satisfaction with “The most adequate material for your needs”, “Advanced PSA coating technology” and “Quick response to needs of you”.

Production Equipment at Mie Plant (1st process)

- PSA Process

- Coloring / Function Added

- Wide Variety of the PSA-film Products with our Coating Machines with a spec of Clean-room, and of General-purpose as well.

- From a Wide Range of Spec Machines for Small lot, to Wide types: 1800 mm width.

- Coating

- Possible thin-film coating (minimum coating thickness 0.5μm ~)

- Ink-jet coating and decorative glass film or mat coating

- Laminating

- Protective film and double-sided tape can be attached with a wide size.

Production Facilities at Mie Plant (Secondary Process)

- Slit Process

- back slit Process

- Various products can be processed by our slitting machines at a timely order in clean-room or general-purpose circumstance.

- Packing and Shipping

- Choice a wide range of package style, case packing, even hanging roll style, our shipment system has completed a direct delivery to your site.

Osaka Factory Production Facilities (primary Process)

- Plain PSA-film Sheet Process

- Carry-in Process

- Very Thick Substrate

- Small lot PSA-film Sheet Process is possible in the form of a Flat sheet

- Adhesive Process (small)

- Supports up to 650mm width, can be processed in small lots

- Lamination (small)

- Supports a maximum width of 630mm and can be laminated in small lots

Osaka Factory Production Facilities (Secondary Process).

- Slit Process

- Back-slit Process

- Equipped with general-purpose slitting machine

- Cutting

- cutting

- back slitting

- Can cut up to 1100mm x 2500mm

- Laminating

- carry-on Process

- Supports up to 800mm width

Nichiei (Thailand) Production Equipment (Primary Process)

- PSA Process

- coloring / Function Added

- Various Products can be Processed by Coating Machines at a Timely Order in Clean-room or General-purpose Circumstance.

- Max 1600mm width

Adhesive Process & Coloring / Function Added

- Slit Process

- Slitting Process in Clean-room Circumstance

- Various Products can be Processed by Slitting Machines in Clean-room or General-purpose Circumstance.

- Cutting