MATRIX Technology

In terms of both "Easy work-ability" of the PSA-films at its lamination to adherent and "The countermeasure against Gas Lifting (caused by swollenness)", the "MATRIX" has been trusted by accumulating results since their coming to market in 1992.

Registered Item: The Series of MATRIX is;

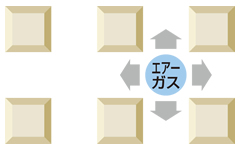

In addition, the gas problem called “Gas Lifting (caused by swollenness)”, which occurs due to the aging or heating process, during like a conservative plastic resin forming stage, becomes cause of the volatile, or air inside. In spite of complete preventive counter measures the “Gas Lifting” cannot be avoided.

However, by using our MATRIX stickers, this is no longer a problem. It has made a revolution in this field by creating that high-performance PSA-film of the next generation.

Features

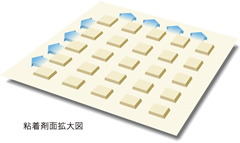

These are designed to allow trapped air bubbles (or if any volatile gas inside) a passage to escape, through the superfine micro-channels which run length and width.

Because of convex shape of the MATRIX, only a small amount of PSA actually comes in contact with the applied surfaces.

Therefore, to maintain our sufficient “green strength”, a specific PSA is selected by our laboratory, which is able to stick with the same strength as our original non-MATRIX products.

Precautions

- To optimize sticking conditions, clean the surface of oily substances, dusts etc.

- Optimal adhesion usually occurs after approx. 24 hours.

- Do not use water before sticking.

- As far as possible, apply pressure on the Label/sticker to the adherent.

- Products quality shall be guaranteed until expiring date. Use them up by then.

- Store in a cool place away from direct-sunlight, as it can damage the products.

- Use only in temperatures above 10℃ to increase operating efficiency.

- Please test our products before make a decision of starting to use.

- Please check the specification of our products before starting to use, as they are subject to change without notice.

- The "MATRIX” is a registered trademark by NEION Film Coatings Corporation.

Cases and Results.

By using convex and concave structure, we are able to create GOOD working efficiency that has NEVER been seen in the past.

Because of the micro-channels in the glue lattice, air is able to escape while the sticker is being applied.

This reduces the occurrence of “bubbles” due to trapped air, which shortens working time. This outstanding property can be reflected in our cost performance.